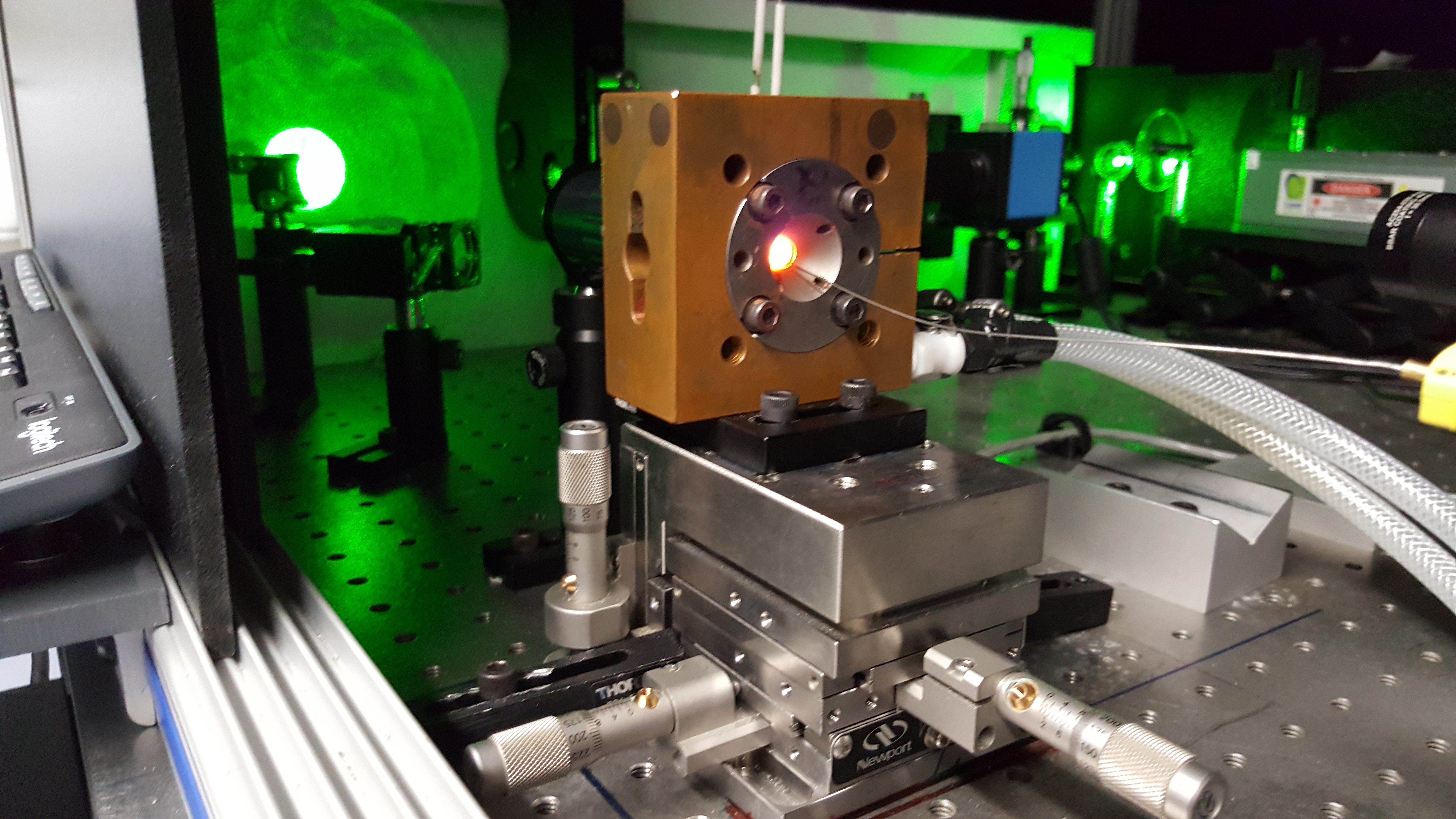

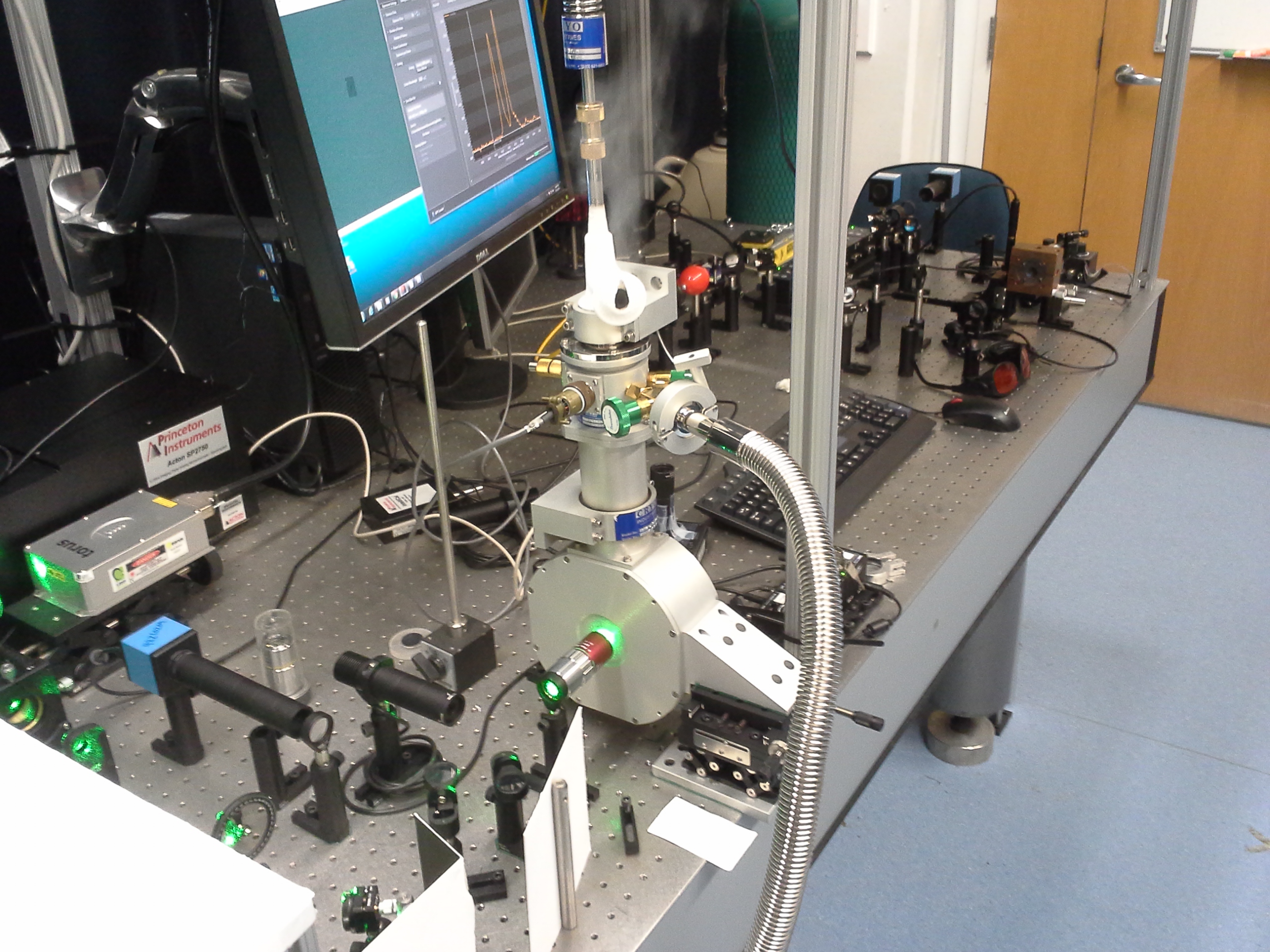

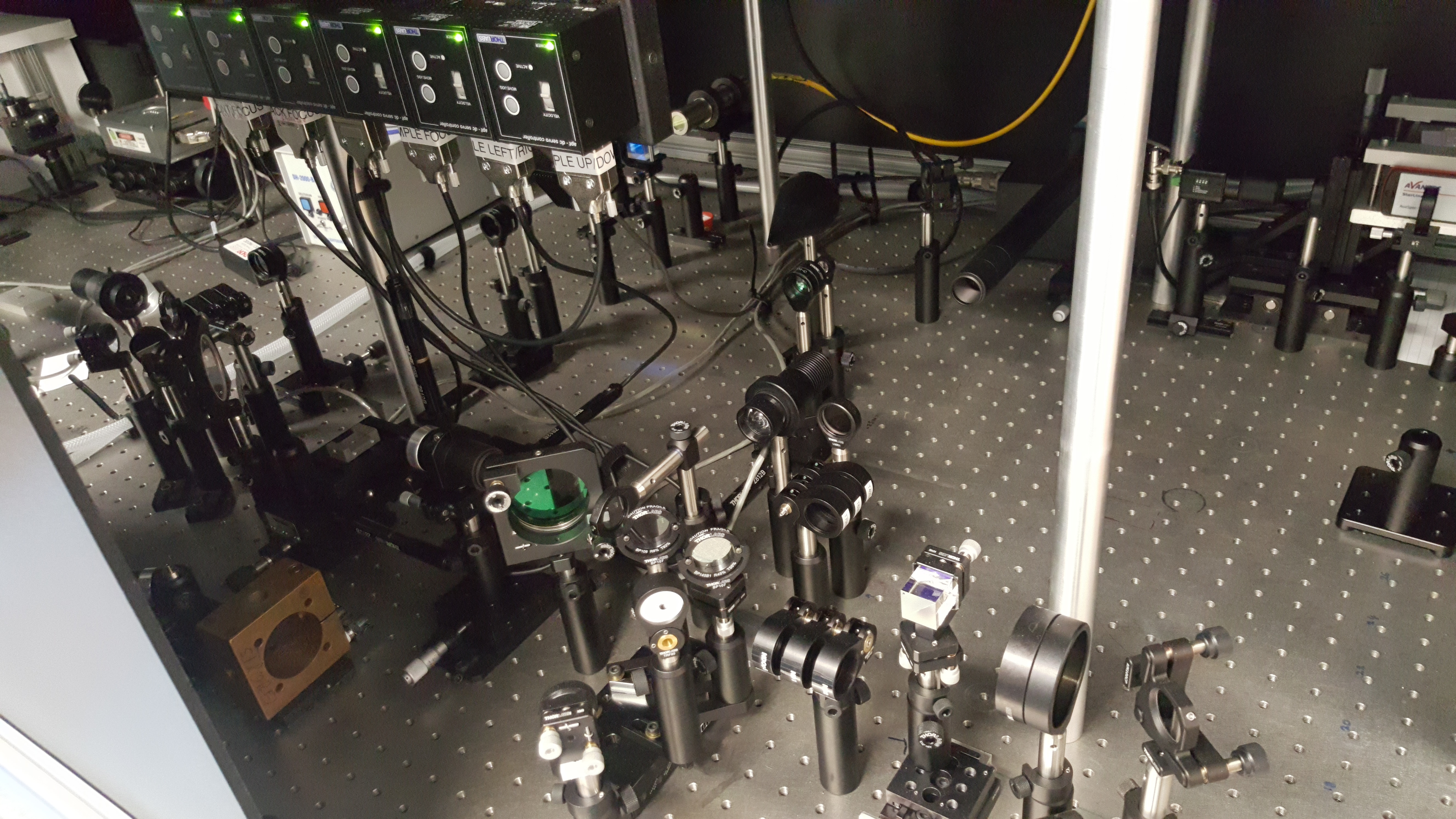

Diamond Anvil Cells

We have a wide range of diamond anvil cells available, with varying degrees of optical access and temperature control options for different applications. For example, low temperatures are achieved within a cryostat (Cryoindustries DAC He cryostat) and high temperatures are achieved using resistive or laser heating (300W IPG IR fiber laser).

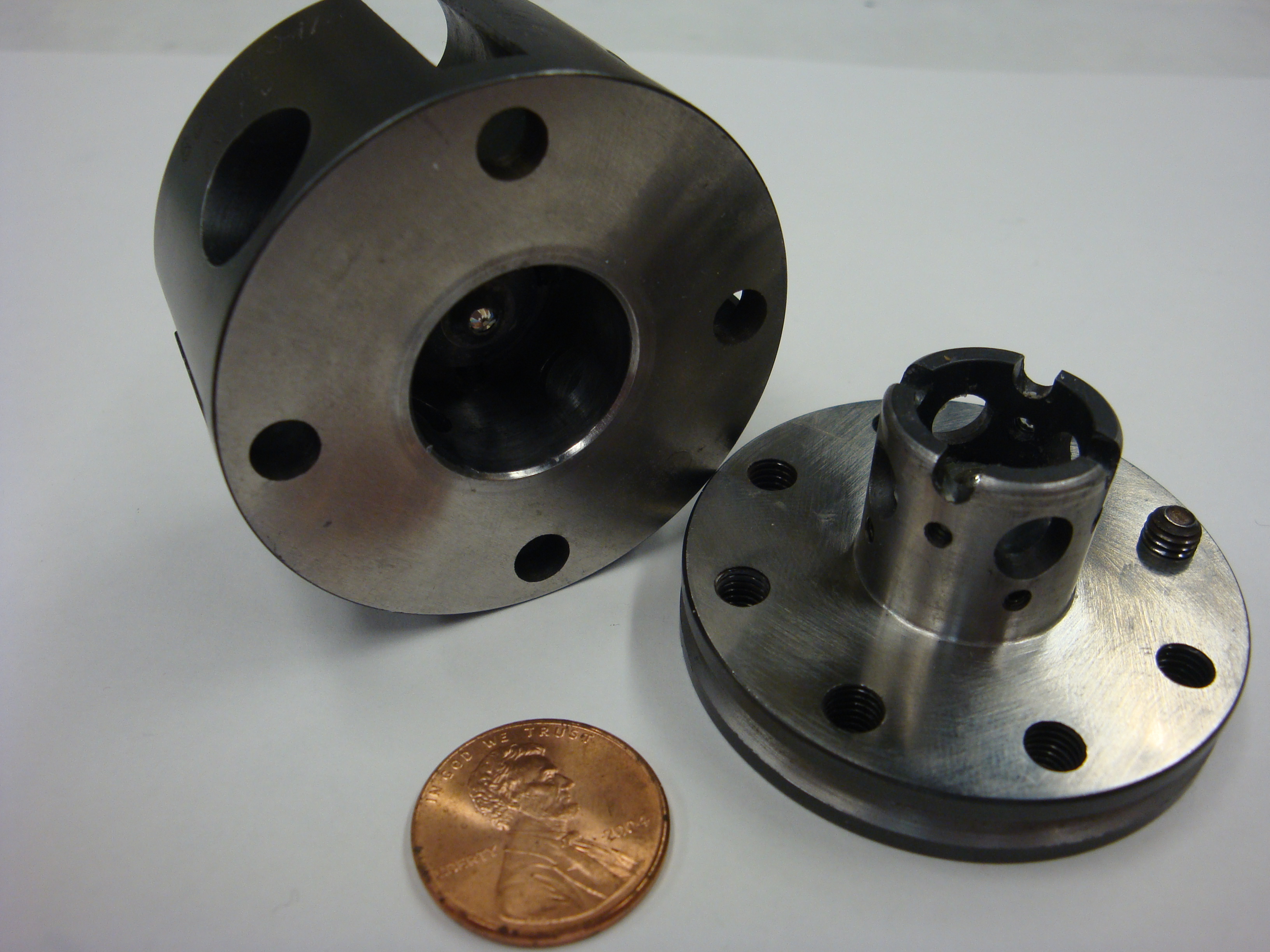

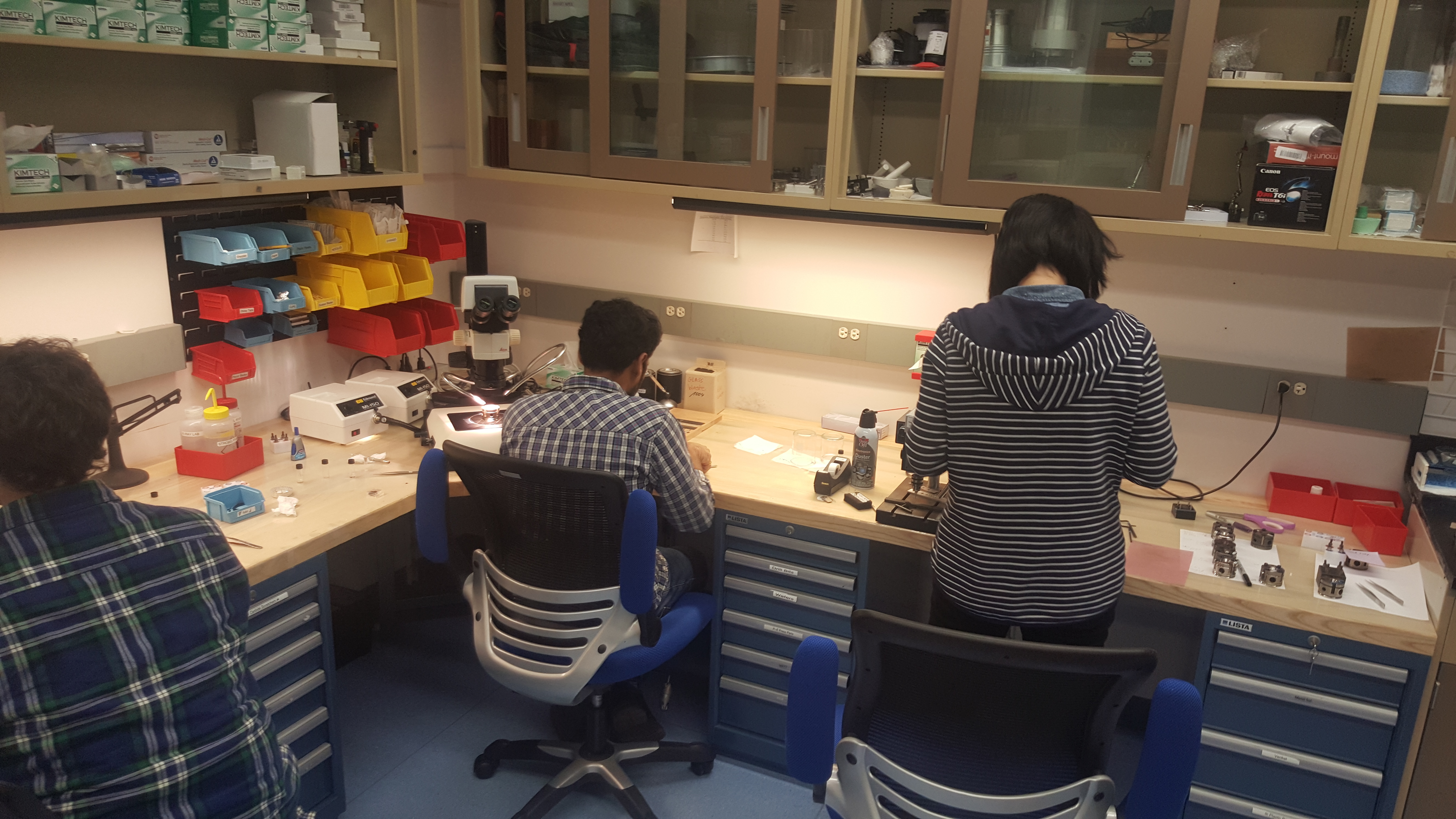

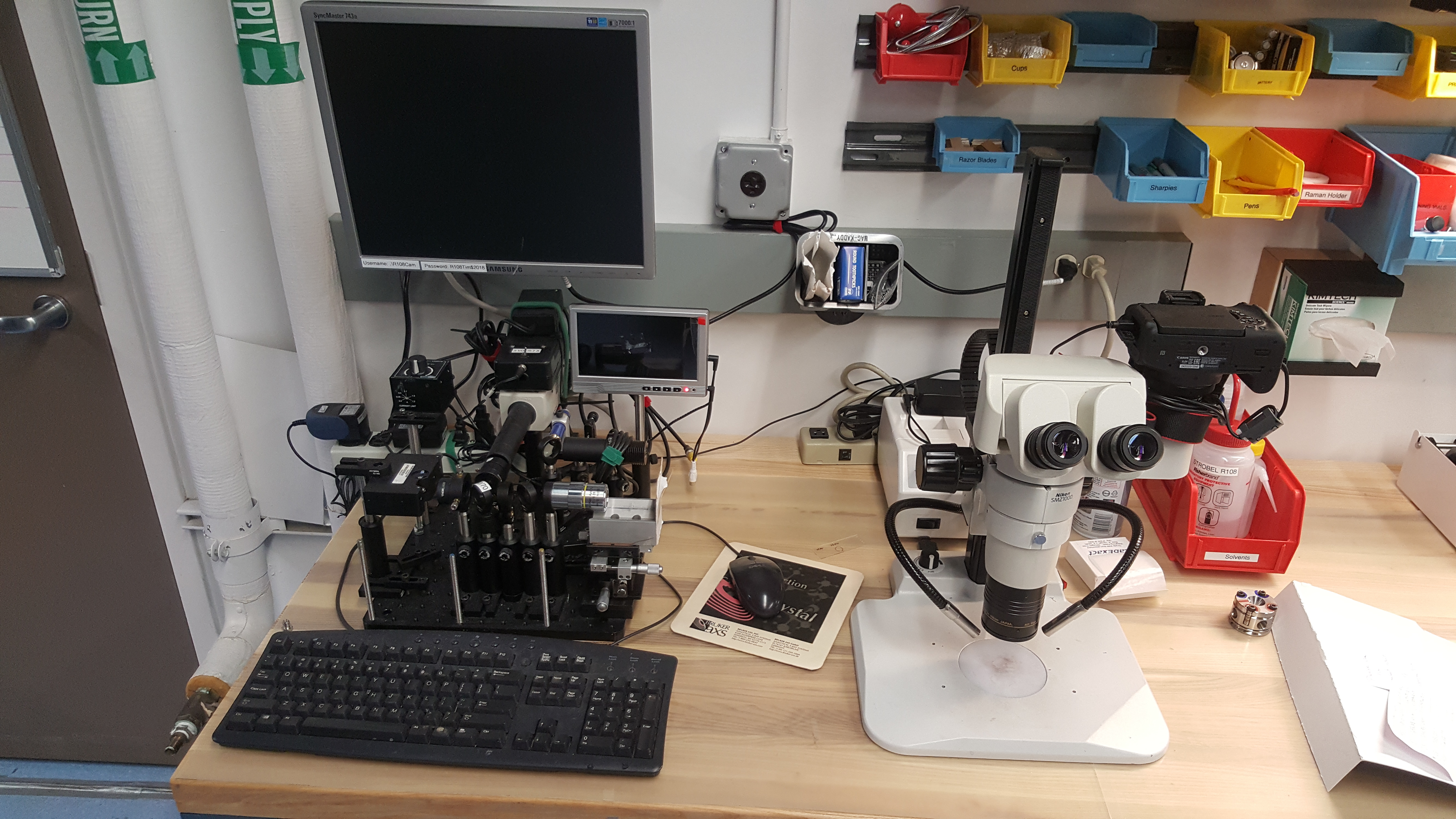

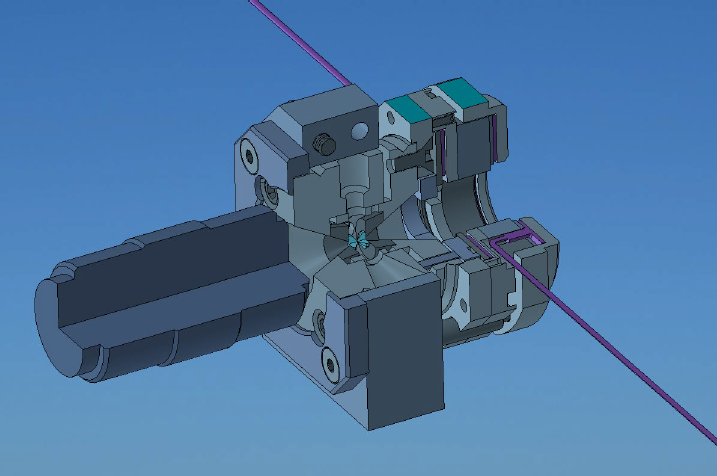

Sample chambers are prepared from metallic gaskets (e.g., Re), which are indented with the help of our portable ruby fluorescence system and drilled with our automated micro laser machining system. The lab is stocked with plenty of microscopes and all of the tool needed to work with micron-sized DAC samples.

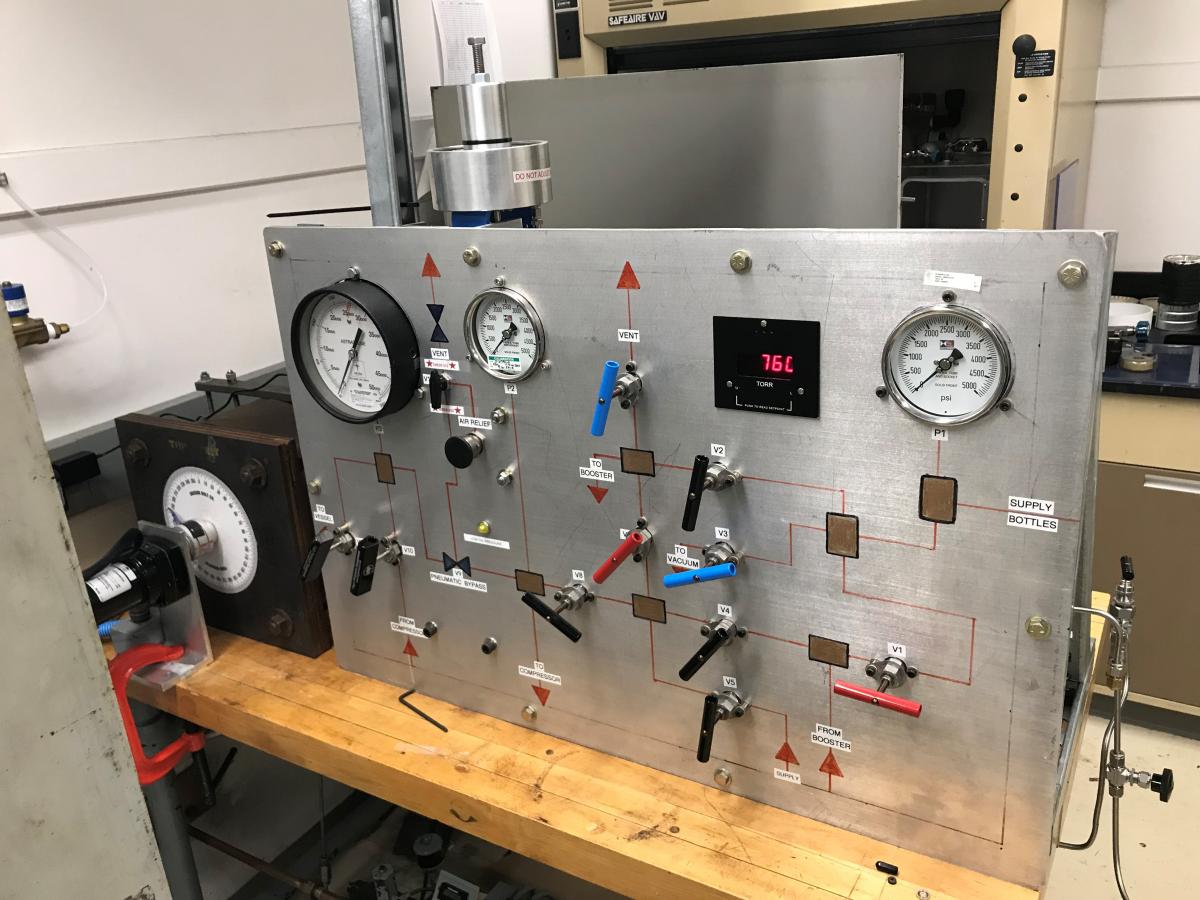

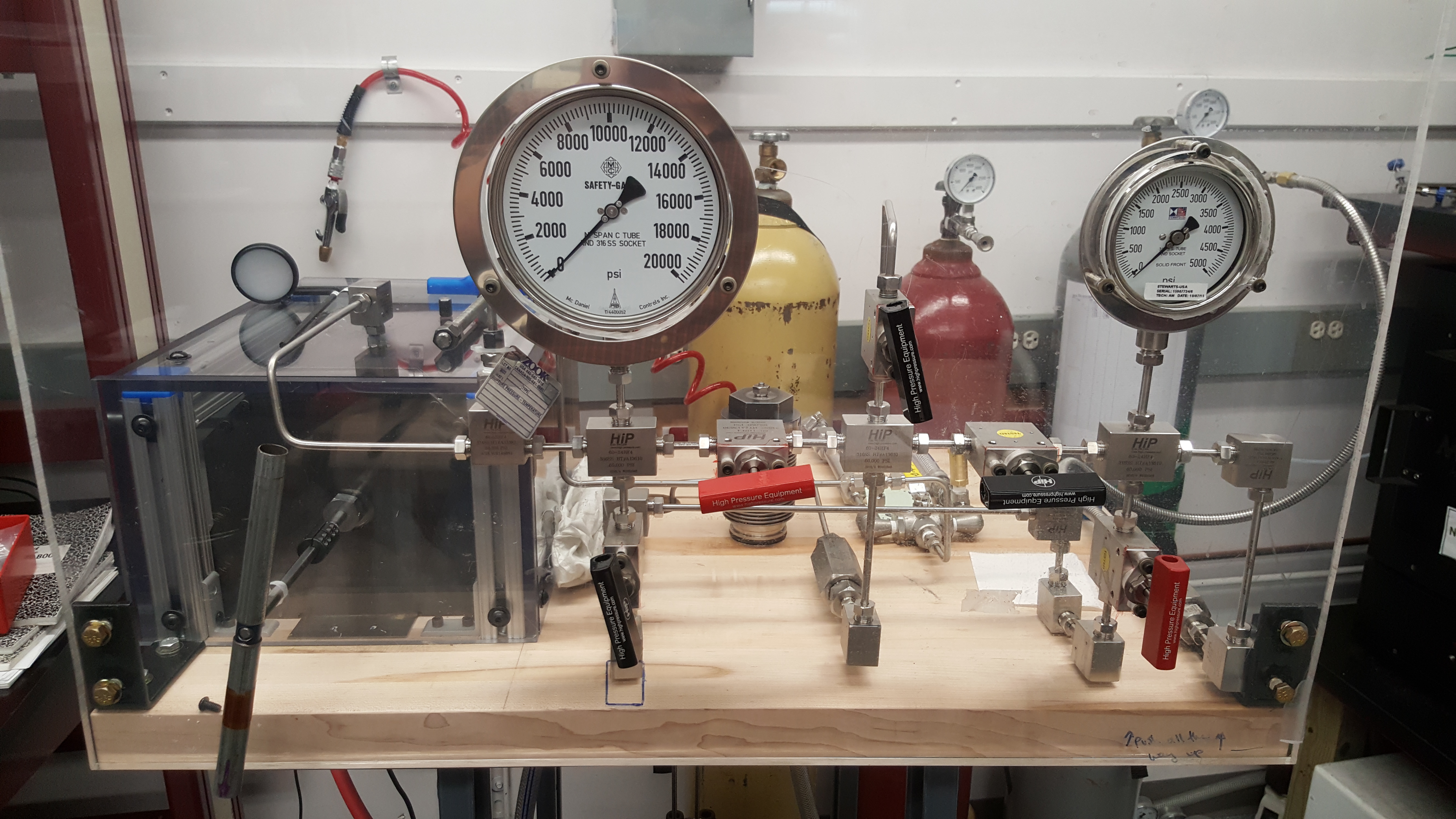

Two gas loading facilities are available to load gases within the DAC to achieve quasihydrostatic conditions (or when gas is part of your sample of interest!).

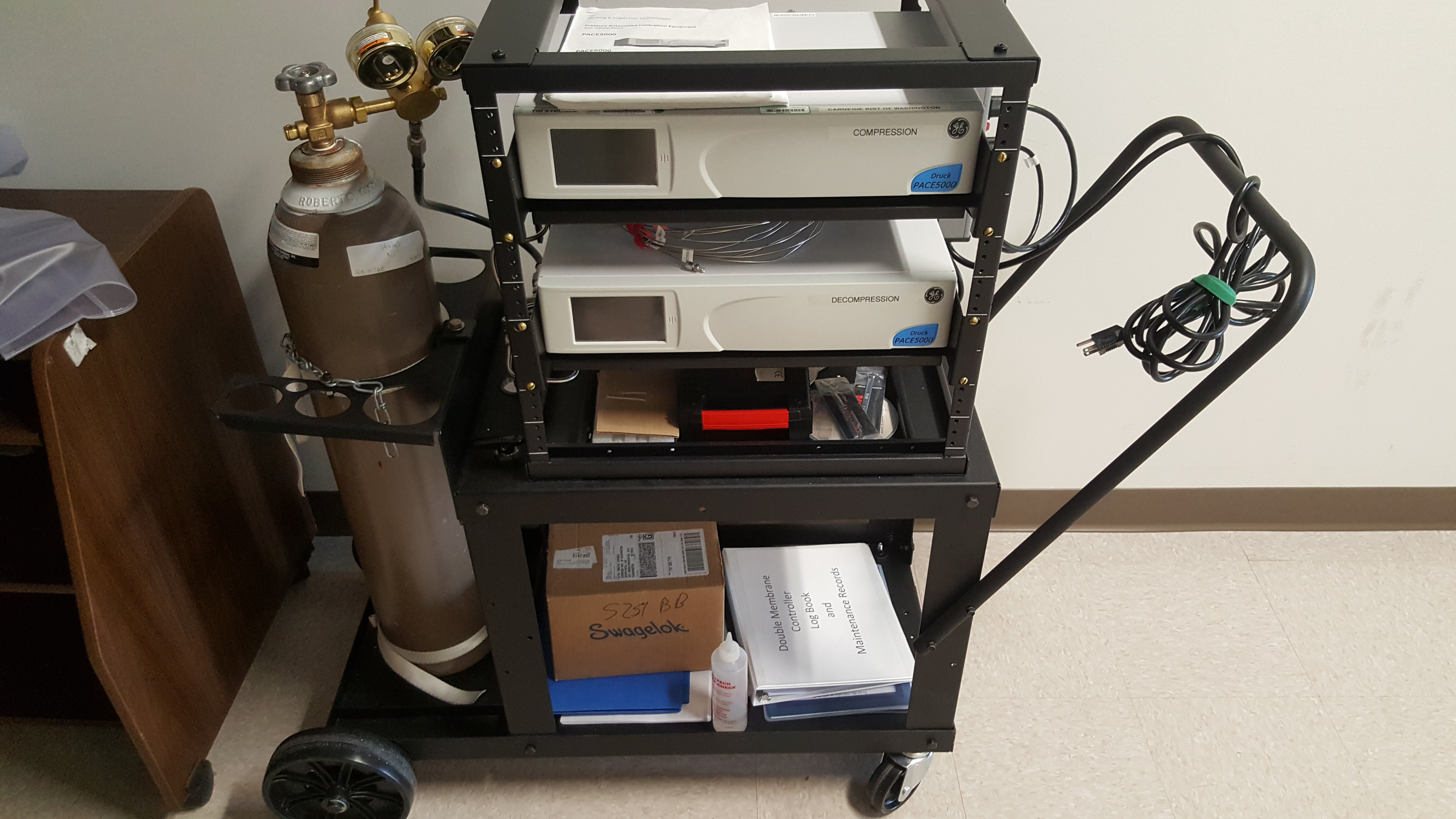

Turn the drive screws of the DAC to generate pressure, or use the Druck Pace5000 pressure controllers, which allow for precise application (or removal) of pressure for membrane (or double membrane) DAC experiments.

Large Volume Press

The 250 ton Paris-Edinburgh Press (VX3) is equipped with a Teledyne Isco syringe pump (30 ml capacity, 30,000 PSI) and Keysight power supply unit (9 V-220 A) and is used for recovering cubic millimeters of samples from high-pressure and high-temperature (HP-HT) synthesis experiments. The ‘conoidal’ anvils, pyrophyllite gaskets and cylindrical graphite heaters are currently used for high-temperature experiments. The typical pressure and temperatures routinely used are 6-9 GPa and 1600K. This setup also has the capability to perform resistivity measurements under pressure using Keithley digital multi-meter. High-pressure experiments to 25 GPa are possible using a metallic gasket with sintered diamond anvils. In collaboration with Yingwei Fei, we also perform materials synthesis experiments using the large-volume multianvil press lab, generating pressures up to 25 GPa and temperatures up to 2300 K. In collaboration with Reini Boehler, we are working to develop novel large-volume synthesis capabilities.

Bulk Solid-State Synthesis

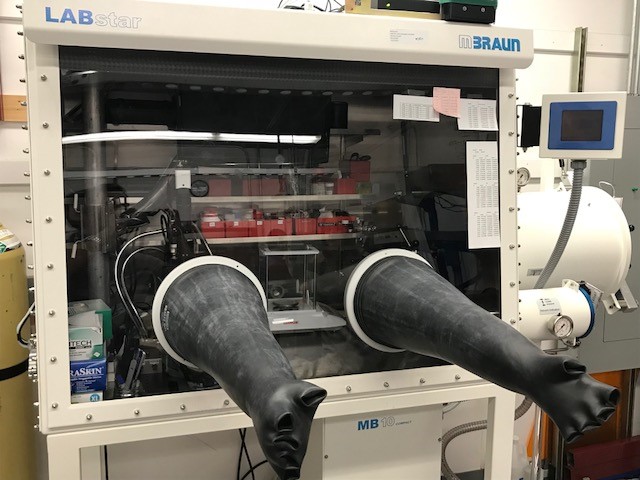

The LABstar glovebox allows for experiments to be conducted and manipulated under an inert Ar atmosphere. The glove box is equipped with two antechambers, one small and one large, to allow for more efficient cycling. The box is equipped with a single column inert gas purification system that maintains O2 and H20 levels below 1 ppm. The interior of the box is equipped with a diamond anvil cell loading stage (camera, monitor, light sources), a balance accurate to 0.001 g, pellet press, and a vacuum sealing system. Available chemicals are maintained in an inventory list stored next to the glovebox.

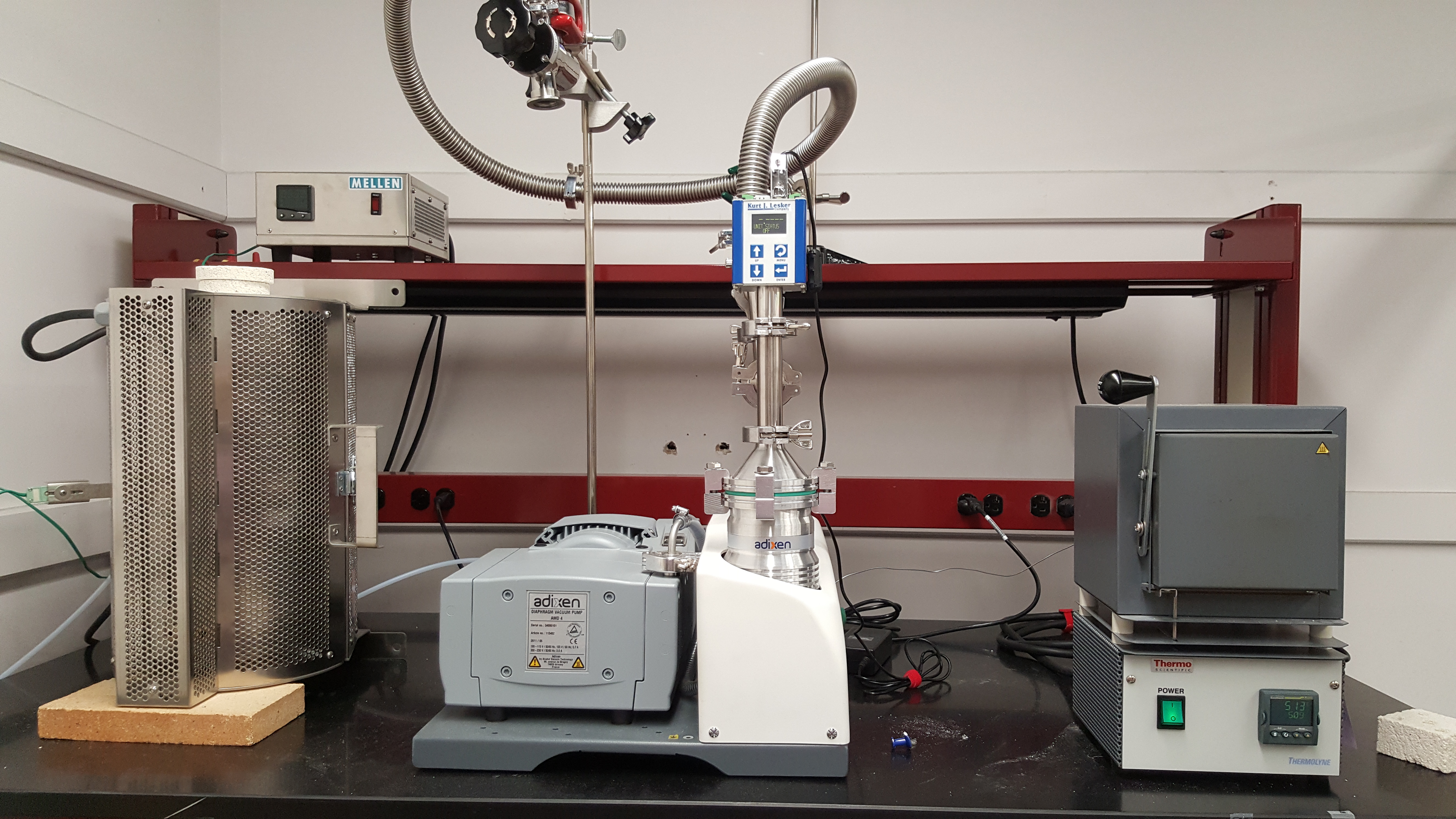

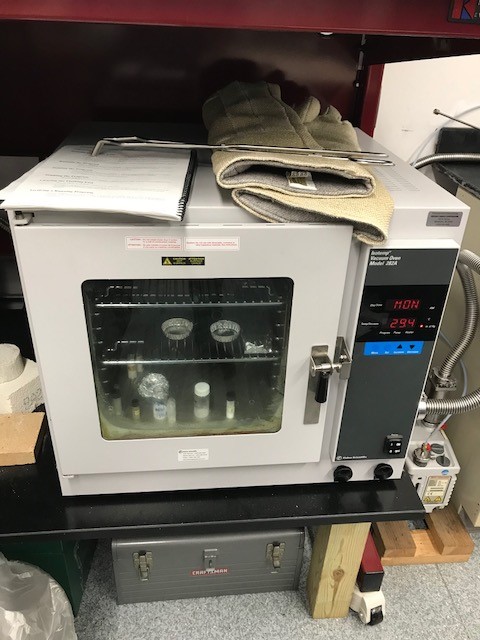

A variety of furnaces and ovens are available for synthesis. The Mellen microtherm furnace is an industrial box furnace setup for solid-state synthesis. The furnace can maintain temperatures up to 1800 °C and heats a volume of 6”x6”x6”. The oven is controlled by an Omega CN7800 controller and can run a variety of temperature profiles including slow heating and cooling. The Mellen split tube furnace operates at temperatures up to 1250ºC in air. The standard orientation of the furnace is horizontal, however, a vertical stand or a bench stand is available. The furnace has fast heat-up rates (30ºC per minute standard) and an integrated dual-display controller, making it easy to use. Tubes are easily attached to the turbo pump for dynamic pumping experiments. The Thermolyne small muffle furnace is the ideal choice for quick runs up to 1100ºC. The digital setpoint controller allows for a variety of custom heating profiles. The isotemp vacuum oven is an ideal setup for general vacuum drying and heating applications. The oven has a depth of 18” and a capacity of 1.5 cu. Ft. The oven can maintain temperatures up to 280 °C and can be monitored with the built-in LED controller. The controller can be set up for programs as long as seven days and can cycle on and off up to eight times per day.

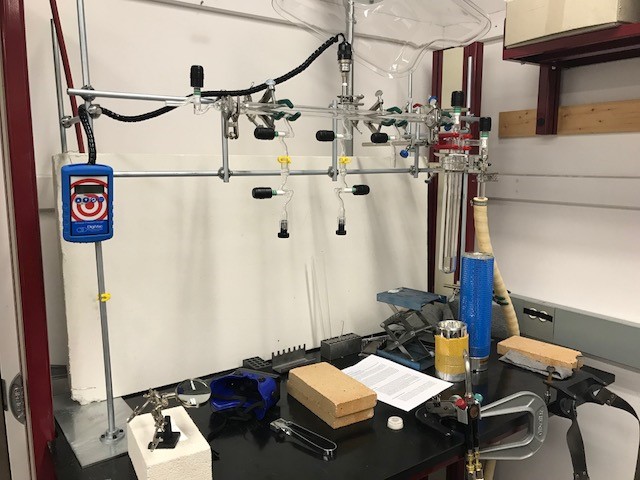

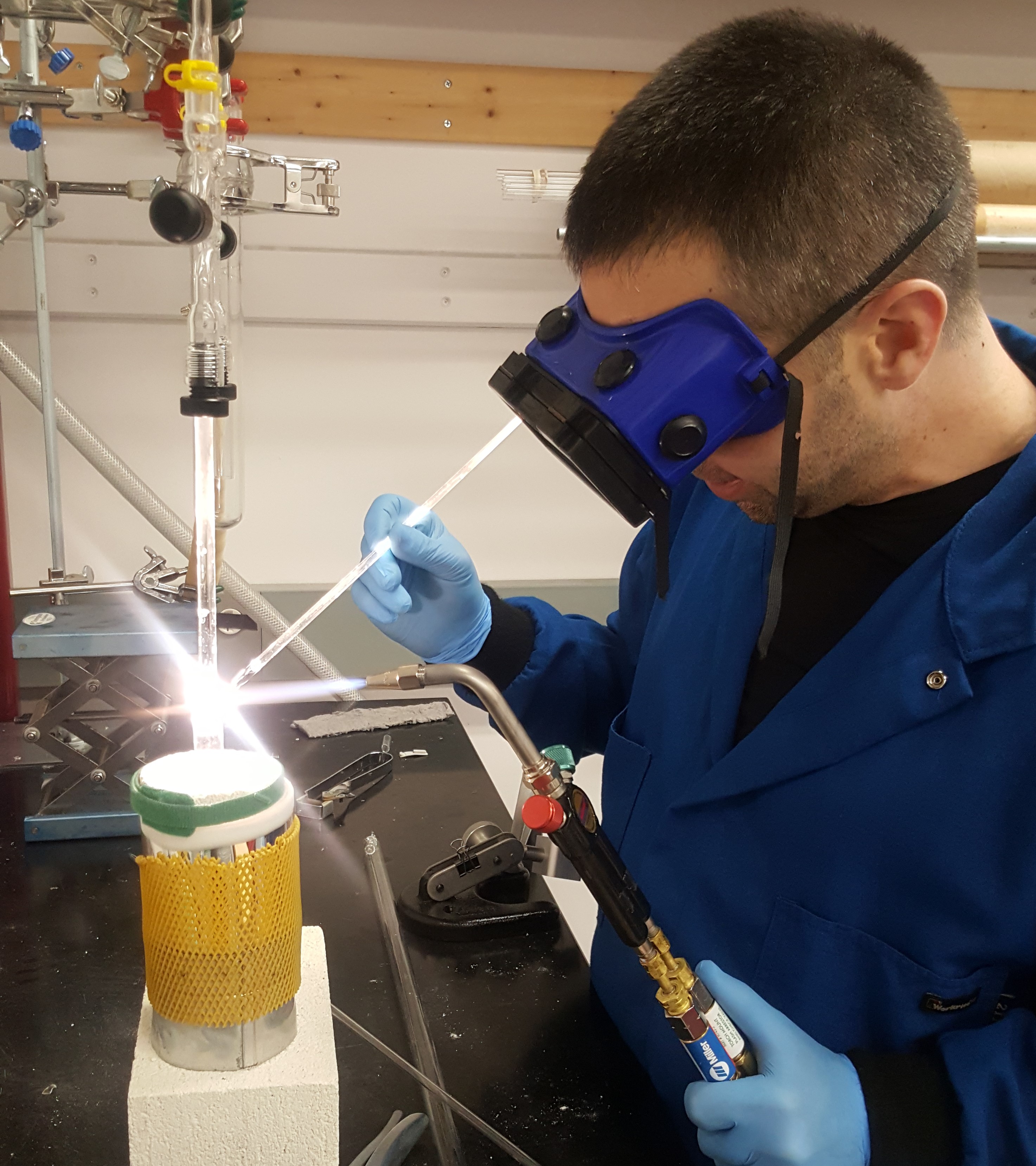

The vacuum sealing line is used to isolate solid-state experiments under vacuum in glass tubing. The line is setup to receive various sizes of glass tubing, evacuate them, and seal the tubing with a hydrogen/oxygen torch. The system can maintain vacuum to at least 10-3 Torr during sealing.

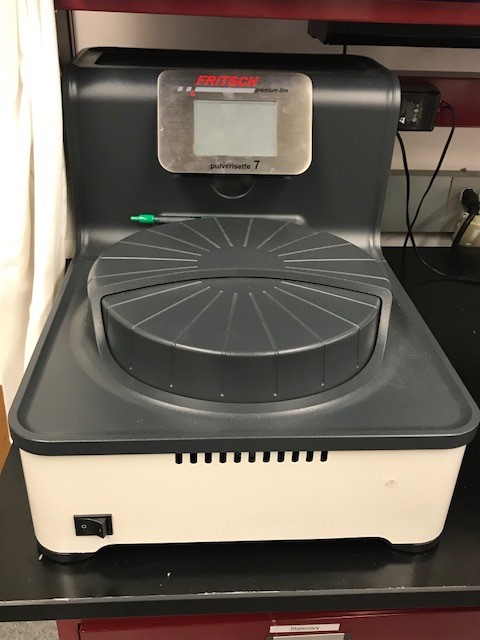

The Fritsch pulverisette is suited for loss-free grinding to 100 nm of hard, medium-hard, and brittle materials. Grinding can be performed dry, in suspension, or in inert gas. The system maintains main disk rotational speeds of 100-1100 rpm and features a SelfLOCK sample chamber for absolutely safe operation. The system can run simultaneously on two samples with a capacity of 30 ml each.

Other

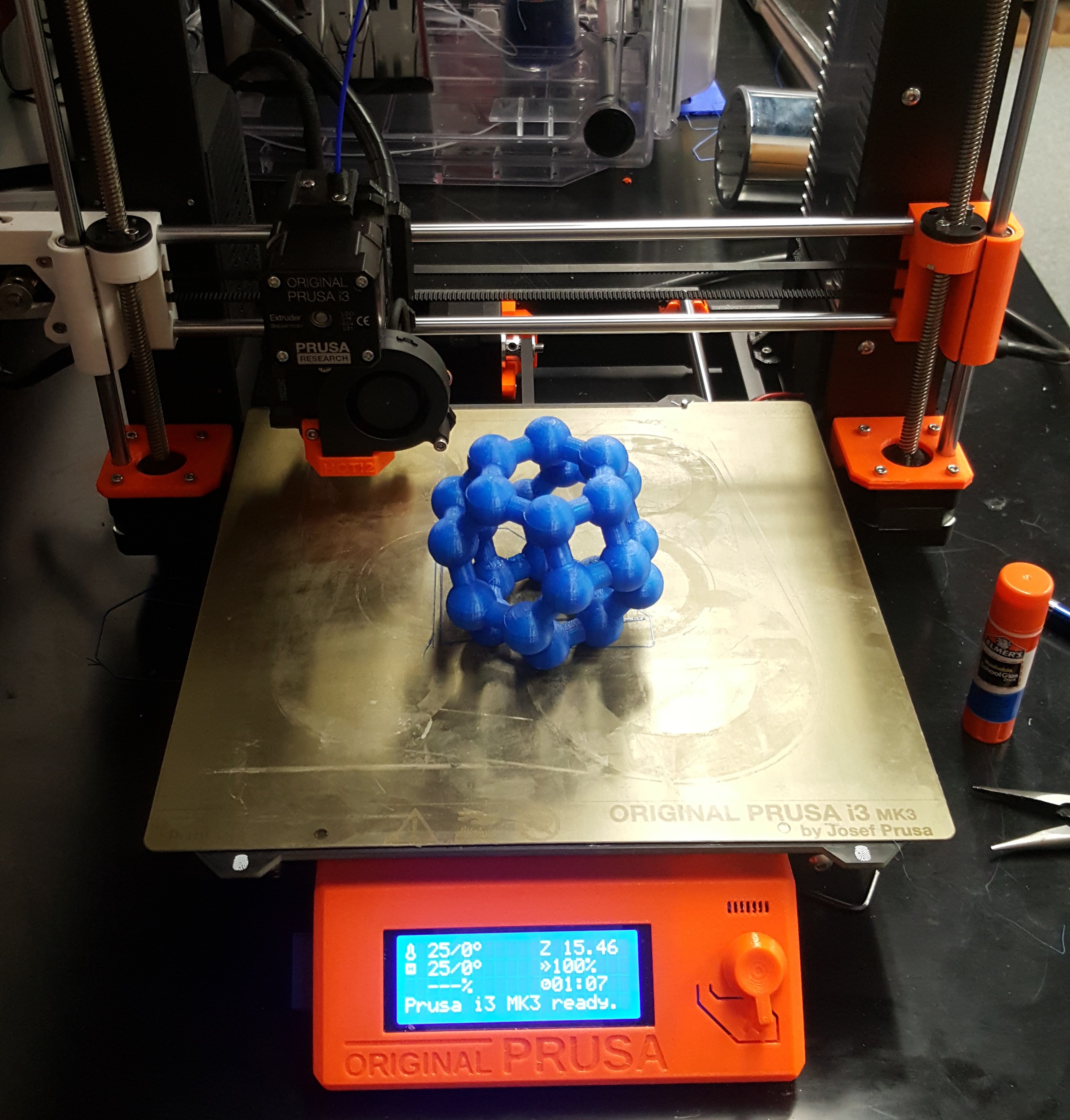

Check out our 3D printing stations for rapid prototyping and for true 3D visualization of the crystal structure you just solved!